Bareroot Supply

As specialists in the production of junior material to the horticultural industry, our focus on bareroot material grown well ensures great performance post planting no matter the supplied size.

We are a longstanding wholesale grower producing environmentally sustainable tree material based on expertise, quality procedures & a genuine commitment to tailoring growing techniques & timeliness of supply to a discerning commercial customer.

As a reputable longstanding wholesale production nursery, we are committed to producing quality material using best-practice production processes.

Situated at Benalla in regional Victoria, we are well-positioned to extend our well-established production philosophy to commercial fruit growers throughout Australia

Our in-ground programs focus on using virus-tested rootstocks produced in the most effective way possible to suit your specific commercial needs.

Building a grow and supply relationship is a two-way street. While we can supply you under traditional terms, our commitment to you is a better experience with a team that is approachable, flexible and highly experienced, all under consultation with you.

You’ll see a business with a can-do attitude, and with people better equipped and process-prepared than others to openly explore the right avenue of supply for your growing conditions, long-term needs and performance expectations.

The Facts

- 125 acres of in-ground production at Benalla

- We are licensed through APAL to use the JM series apple rootstocks

- We are a Silver sponsor of Fruit Growers Victoria (FGV)

- We practice extensive IPDM at all sites & regenerative farming techniques at Benalla

- Our staff have extensive horticultural knowledge & in-ground experience.

- We supply trees to suit your needs - for old & new growing systems.

- We also have the ability to grow spring buds, one, two and three year old fruit trees

Our Material

We are licenced through APAL to use the JM series 'new generation’ apple rootstocks JM1 & JM7. We also have Quince A and Quince C rootstocks available. All of our material is virus tested.

We supply true to type, virus-tested material.

With scientific developments in rootstocks, processes, Integrated Pest and Disease Management, soil management and inoculation, we aim to deliver quality trees that establish quickly, produce early, and perform for many years.

We provide the cleanest material to you using virus certified rootstocks sourced from registered stool beds or tissue culture.

We also use the latest advances in microbiology employing drip irrigation on every row and interplanting between rows to ensure the healthiest material. A program of inoculation in autumn means that that there is an uptake of beneficials to the trees prior to winter when they are dug and supplied.

Available Rootstocks

Plum

Myrobalan H29c

Marianna GF6-1

Peach

Golden Queen

Tatura 204

Pear

Quince A

Quince C

Quince Eline

Calleryana D6

Apple

JM1*

JM7*

Merton 793

MM 111

M9

M26

Our Expertise

In-ground Production Manager, Shayne Van Der Klift has over 25 years of in-ground production experience, so we are well equipped with passionate people, beautiful soils and ample water to produce the highest quality fruiting material that is virus-tested, true to type, structurally sound and free of pest and disease.

Shayne heads a flexible business structure that ensures the varied talents of the team are used to the best effect, bringing technical expertise, accountability, and communication to the fore. He leads an operation where staff attend regular field days, symposiums and research days to further improve knowledge and understanding of industry trends, particularly in light of scientific advancements in machinery or techniques.

Production planning and project management is done at our head office in Narre Warren East. Skilled project managers and technicians assist in every element of the production process.

Being accountable is also about being approachable. We want to ensure we grow to the needs of the market and to the high quality our customers expect.

All in-ground production is undertaken at our Benalla site.

The Digging Process

During the months of May to July, our early cold morning starts result in bareroot trees dug for the days grading.

Using minimal people, trees are lifted with minimal disturbance to the soil. Each year we are improving working efficiencies with introduced technology making a difficult, labour-intensive job easier and quicker.

The seeded interrow is used for biodiversity reasons as it helps reduce compaction and holds the soil and nutrient in place during rain and wind events while at the same time allowing organic matter to break down into the soil.

This is a close-up of the digging mechanism. Trees are undercut, gently lifted and soil is removed. The trees move up a belt system where they are then collected and piled on specially made stillages.

The digging machinery we use ensures minimal damage to root systems, branches and soil.

This is a close-up of the tree collection process off the converyor belt, where trees are collected and placed on the stillage. Note that all the soil is removed and left in the paddock for reuse.

Because our process creates minimal disturbance to the soil, paddocks are swiftly ready for rejuvenation and then reuse. Trees remaining in adjacent rows are free-standing, tall and uniform - ready for harvest.

It is a straight-forward process to lift trees during the winter. Extra care is taken to lift the trees from the ground so that they are in perfect condition for the next stage of their journey. Minimal handling reduces stress therefore increasing material resilience.

Trees are grown to a standard note the caliper and the branch structure. Tree identification tags are on the first and last tree in a batch to ensure there are no product mix-ups.

Once collected, trees are graded. Our staff tie material into easy-to-handle bundles of 5 or 10. They record the consistency of the batch, caliper size and rate the quality of root systems. It is a considered process where each tree is diligently examined for quality, size and health, as was the case with this Liriodendron stock above. Only the best trees are delivered to customers.

Trees have been graded and bundled into groups of 5 or 10. They are then placed onto pallets and tied down securely to eliminate excessive handling. Keeping the trees moist during the digging and delivery process ensures a perfect tree for the next stage of its journey. The easier trees are to handle the less stress is experienced which results in better growing outcomes.

Orders are transferred directly onto the pallets and then tied down securely. Less manual handling at this stage reduces the stress level of bareroot material.

When the complete order is assembled, bundles and palletised trees are then delivered to the customer as quickly as possible.

Our Benalla Production site is located at 1317 Mansfield Rd, Benalla.

To find out more about our business and the opportunities we can provide around bare root tree supply and in-ground fruit tree contract growing, please direct your enquiry to Shayne Van Der Klift here or by mobile on 0419 314 115.

To download our current flyer on commercial in-ground production please click here.

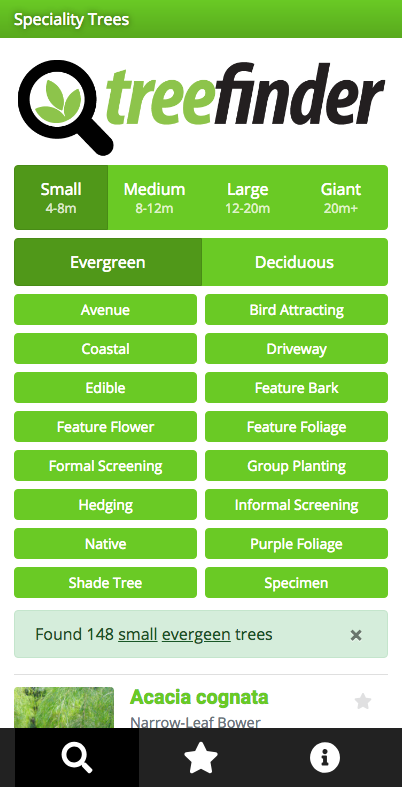

Treefinder can help you identify the perfect tree for your next project!

With over 400 tree varieties for review, the Treefinder app enables you to conveniently browse and compile a list of trees suitable for a number of common landscaping uses - from attracting birds to creating a formal screen or hedge. By selecting desired size, foliage, and a few categories, Treefinder opens up a world of possibilities.

Once you've found the perfect tree you can click through to our website for more information, availability and a quote.

We are specialists in the environmentally sustainable production of premium quality advanced landscaping trees and screens.

For more than 48 years Speciality Trees has been a leader in the production and supply of advanced environmentally sustainable, containerised landscape trees for local government, the landscaping industry and retailers.

Learn more